JANUARY 2004

Alan detailing the batten support blocks

|

Chief sealing the hard to reach areas around the fuel tanks

|

Steam bent White Oak sponson support

|

Bent Oak piece in place

|

Batten support blocks in place.

|

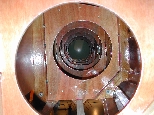

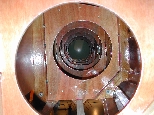

Looking down the keel

|

Alan making the rudder attachment bracket

|

Alan installing the rudder attachment bracket

|

Left Sponson

|

Rob with Ron Jones laying out a sponson chine

|

The Master's still got it!

|

Steve & Rob re-trimming the bow shelf

|

Larry trimming some bottom battens

|

Non-trip chine discussion

|

Sponson chines & batten layout

|

To Do List!

|

It's taking shape

|

Eric Compton (Steve's son) sealing the inside of the sponsons

|

Rob, Larry and Dixon Schwenk fitting the batten for the non-trip

|

|

Non-trip battens at transom

|

Rob 'fine tuning' the angle

|

MARCH 2004

Using pull plane, Rob gets the sheer clamp down to the 45 degree angle

|

Look at those chips FLY!!!

|

Sponson chines

|

Non-trip chine intersection (where the chine, side and bottom meet

|

Right side non-trip just before the batten were attached...note the notch left from the router during the final depth/angle cut

|

Battens attached! Watch soon for the skin!

|

Steve C drilling the non-trip chine skin

|

Right non-trip...note the plank filling in on the side. This is where the trailer bunk will be located so as not to collapse the side skin.

|

Alan with friend Brian and Lloyd Collins.

|

Steve and Alan applying Hysol to a shim

|

Chief, Alan and Steve tightening the transom bolts

|

Steve drilling the holes for the rudder bracket...Alan is making sure he's SQUARE!!!

|

Inside reinforcement for the rudder. This ties frame #17 to the transom to spread out the stress.

|

Steve is transfer punching the inside angle aluminum

|

Rob, Chief and Brian checking out the very first installation of the rudder!

|

This shows the position of the steering arm

|

MAY 2004

New 17 inch Steering Wheel with the newly rebuilt Casale steering box

|

Steve and Chief bolting down a right sponson chine

|

Chine bolt detail

|

Steve installing a 3/8 inch wood dowel to affix the front of the chines

|

Rear cowl moulds with extensions

|

Another picture of glue drying!

|

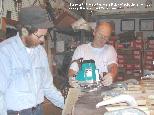

Steve is using the Stout Tool STX100 X-Band 18 volt cordless bandsaw to trim the excess from one of the bottom aluminum skins.

|

Mark Evans is the spokesman for Stout Tool and generously let us use this great tool to see what applications we had for it!"

|

Corky Peterson explains to the Chief some of the functionality of our brand new trailer!

|

Trailer on tilt

|

Left side non-trip glued in place"

|

OCTOBER 2004

Things are taking shape!

|

The side of the boat just before the bandsaw work.

|

AFTER the bandsaw and in place

|

Left sheer clamp in place

|

Steve Compton marking out the notch and angle at frame #1.

|

The Chief marking where the the air trap stops so we don't waste glue!

|

Alan sealing up the bottom of the side battens with West epoxy where it will be verrrry hard to get to once the sides are on.

|

Rob & Peter back drilling the right side

|

Joe Winkler and Lloyd Collins discussing hydro stuff

|

Alan filling in voids before the side goes on

|

The drill Brigade

|

The rudder done and in place.

|

Alan and Stuart applying glue to the right side

|

Alan installing the right side

|

Side/Non-trip, an inside view

|

Larry pilot drilling the left side

|

Left side installed

|

NOVEMBER 2004

Larry sanding the bottom while Chief checks it for high spots

|

Was Larry the only one sanding?!

|

Transom after extension angle applied and drain holes drilled.

|

Station #8 Right side glue block.

|

Rob cutting the excess tube at the drain holes

|

Filler block at start of non-trip

|

Rob at the mill shaping the 5/8" rudder shim.

|

Right air trap towards fuel tank.

|

Right Sponson

|

Chief, Steve and Larry Spreading the Hysol on the bottom skin

|

Alan was busy mixing while the rest of us spread it!

|

Steve continuing to spread the Hysol

|

Ready to GO!!!!!

|

Larry, Rob and Alan laying the aluminum in place

|

Our benefactor, Harold Foss

|

Dixon lifting the mock-up Merlin out of the Bardahl so we could see better.

|